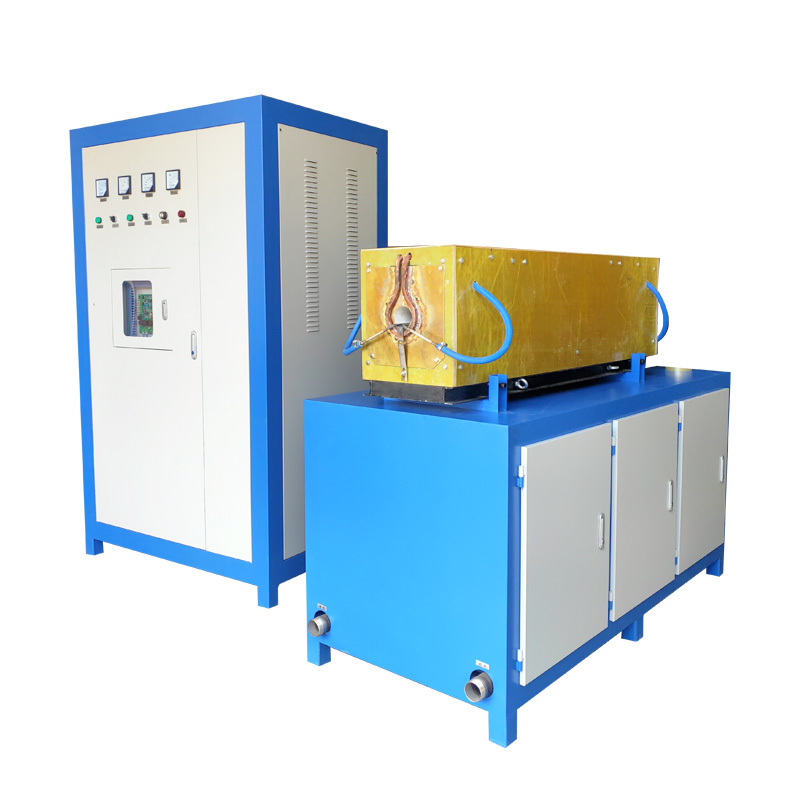

The main components of the bar local induction heating furnace:

(1) Intermediate frequency induction heating power supply

(2) Compensation capacitor and forging furnace table

(3) Induction coil, guide rail and cover

(4) Pneumatic feeding mechanism of bar induction forging furnace

The working principle of the bar local induction heating furnace:

The intermediate frequency induction heating power supply converts the three-phase power frequency alternating current into direct current through the rectifier circuit, and then outputs the single-phase intermediate frequency alternating current through the inverter circuit to supply the intermediate frequency coreless induction furnace, and then uses the principle of electromagnetic induction to place the workpiece in the alternating magnetic field. It generates eddy current and generates heat, which meets the heating requirements of smelting, quenching, and diathermy.

Main features of bar local induction heating furnace:

The medium frequency induction diathermy furnace has the advantages of energy saving, fast heating speed and no oxide layer. The heat penetration is complete, the temperature of the workpiece surface is consistent, and the performance is more stable.

Application areas:

[1] Forging heating: used for heat penetration of bar, round steel, square steel, steel plate, heating, on-line heating of blue quenching and blanking, local heating, on-line forging of metal materials (such as gears, half shaft connecting rods, bearings, etc. Precision forging), extrusion, hot rolling, heating before shearing, spray heating, hot assembly, and overall quenching, annealing, and tempering of metal materials.

[2] Heat treatment: mainly for shafts (straight shafts, variable diameter shafts, camshafts, crankshafts, gear shafts, etc.); gears; sleeves, rings, discs; machine tool screws; guide rails; planes; ball joints; hardware tools Surface heat treatment of various mechanical (automobile, motorcycle) parts and quenching and tempering, annealing and tempering of metal materials as a whole.

浙公網安備 33038102331513號

浙公網安備 33038102331513號